AUTO ON/OFF VALVES

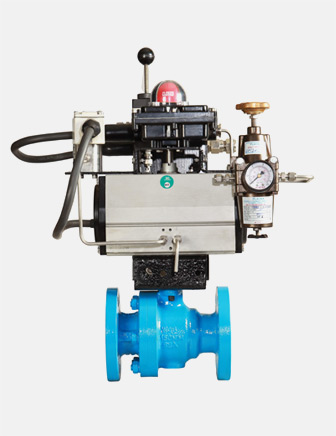

Automated On/Off Valves are used to replace manual valve to reduce the man power and operating time in a process plant, where an auto on/off valve can be operated from a control room through PLC controller using system logic control without human interference.

Actuator Types:

- Pneumatic

- Pneumatic Rotary: Ball, Butterfly, Plug Valves, etc..

- Pneumatic Linear: Globe and Gate Valves, etc..

- Electrical

- Electrical Rotary: Ball, Butterfly, Plug Valves, etc..

- Electrical Linear: Globe and Gate Valves, etc..

Restrictions:

- Electrical Actuators are not suitable for applications, where operating timing is essential in a sequence of operation.

Actuator Requirements:

- Pneumatic Double Acting – Safe Work / General Purpose

Application: Non critical pipeline on/off valves – general purpose automation

TRIP VALVE & SHUT DOWN VALVES

Automated Trip Valves and Shut-Down are used in critical applications, where a system or a valve needs to be closed / shut-down immediately at minimum operating time on emergency signal / command from a supervisory logic controller in a process plant.

Actuator Types:

- Pneumatic

- Pneumatic Rotary : Ball

- Pneumatic Linear: Globe

Restrictions:

- Electrical Actuators are not suitable for shut-down valve applications, where the valves to be closed immediately at the time of emergencies.

Actuator Requirements:

- Pneumatic Double Acting – Safe Work / General Purpose

Application: Non critical pipeline on/off valves – general purpose automation

EMERGENCY RELEASE VALVES

Emergency Release Valves are used in applications, where in-case of emergency the valve to release / open the pipeline fluid to safe guard the system / equipment immediately.

Actuator Types:

- Pneumatic

- Pneumatic Rotary: Ball, Butterfly

- Pneumatic Linear: Globe

Restrictions:

- Electrical Actuators are not suitable for emergency release valve applications, where the valves to be opened immediately at the time of emergencies.

Actuator Requirements:

- Pneumatic Single Acting / Spring Return – Air (or) Power failure to open

Application: Fire water circulation systems in BMS, Level controllers, Draining systems, Pressure release applications, Air vent applications, etc..

MODULATING CONTROL VALVES

Modulating Control Valves are used in applications where the valves required to be regulated with respect to the input signal from the temperature controller, pressure controller, level controller, flow controllers, pH controller, etc.. Here the regulation is done using analog signals.

Actuator Types:

- Pneumatic

- Pneumatic Rotary: Ball, Butterfly, etc..

- Pneumatic Linear: Globe and Gate Valves, etc..

- Electrical

- Electrical Rotary: Ball, Butterfly, etc..

- Electrical Linear: Globe and Gate Valves, etc..

Restrictions:

- Modulating Control Valves are directly not suitable for emergency release / shut-down applications.

Actuator Requirements:

- Pneumatic Double Acting & Spring Return Actuators

- Electrical Actuators: Power to Open and Power to Close

Application: Temperature controller, pressure controller, level controller, flow controllers, pH controller, etc..

THREE POSITION AUTO VALVES

Automated valves can be customized for special application like coarse – fine adjustment, typically for batching operations or processes.

- The Actuator will be electrical quarter turn (or) pneumatic spring return type (or) 3 Position Mechanical Stopper Pneumatic Actuator.

- The operation sequences fixed from full open, partial open to full close.

- Infinite intermediate positions are possible with the limit switch.

- It can be fine tuned to the application easily.

- The settings can be changed at site with ease, by simply adjusting the third cam provided for limit switch.

TAMPER PROOF MANUAL VALVES

Tamper proof manual valves are manual valves fitted with supervisory / limit switches to provide the position of the valve to the control system / logic.These valves are used in critical fire water circulation systems, where the manual valve has to be kept open continuously. The limit switches (SPDT) mounted on top of the manual valve gets in contact with the valve shaft / handle or hand wheel gear box and provide NO / NC feedback to the control system stating the position of the valve.

If anyone tampers the position of the valve, the same provided as the feedback to the control system that the valve is in open / close position.

The typical usage of the tamper proof manual valves is in a fire water circulation system in Building management system (BMS).

Limit Switch / Tamper Proof Switch Types:

- 1 NO + 1 NC SPDT Switches

- 2 NO + 2 NC DPDT Switches

- Proximity Sensors ( NO / NC)

Application: Fire Water Circulation Systems in BMS and Critical application where the valve to be in either open / close position unaltered during operation.

CUSTOMIZED APPLICATION VALVES

Automated valves can be customized for special application with respect to customer logic circuits and system requirements. Any type of valves, gates and dampers

Actuator Types:

- Pneumatic Rotary & Linear

- Electrical Rotary & Linear

Application: Any application as per customer system requirements.

Example: Batching Control System, Inching Application, Remote Control Valves, Wireless Switching Valves, Scada Control Valves, etc..

RETROFIT EXISTING MANUAL VALVES TO AUTO VALVES

Retrofitting valves with new actuators and/or manual valves to automate them presents numerous advantages:

- Recalibrating muscle/actuation to ensure actuator operation, in line with changing valve torques

- Additional diagnostics to monitor the health of the valve

- Reduced operational / maintenance costs

- Increased safety and visibility on the health of the actuator

VALVES

Quarter Turn

- Ball

- Butterfly

- Plug Valves

- Dampers

Multi Turn

- Gate

- Globe

- Knife Gate

Actuator

Quarter Turn

- Electric - Quarter Turn &Multi-turn

- Pneumatic - Rotary and Linear

- Hydraulic - Rotary and Linear

Accessories

Pneumatic

- Solenoid Valve

- Limit Switch box

- Air Filter Regulators

- Flow Control Valve

- Quick Exhaust Valve

Electrical

- Limit Switch

- Torque Switch

- Push Button Starter

- Auxiliary Switch

- Modulating card

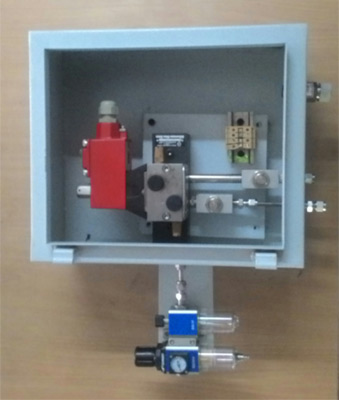

PANELS

We provide pneumatic control panels and PLC logic controller panels as per customer requirements.

Types

- Solenoid Valve Control Box

- Emergency Shut-down valve – pneumatic sequential logic control panels

- Solenoid valve box with logic controls and Relays

- ABB PLC control panels including programming installation &commissioning as per customer logic controls

- Automated valves + pneumatic / electrical control box

- Automated valves + PLC control panels